How to demonstrate comparability for ATMPs?

- 18 May 2020

- advice, API, approach, ATIMP, ATMP, change, CHMP, clinical, comparability, data, development, drug product, drug substance, efficacy, EMA, exercise, final, finished, GMP, manufacturing, methodology, non-clinical, pivotal, process, product, profile, program, quality, RBA, risk-based, safety, scientific, site, stability, stage, statistical, studies, transfer,

CHMP scientific advice questions are often related to the suitability of comparability proposals following changes to ATMP manufacturing processes or due to introduction of additional manufacturing sites.

Manufacturing process changes may encompass improvements/change in

- equipment,

- raw materials and critical starting materials such as the cells or the vector or their suppliers,

- manufacturing process scale or

- product stability.

Such changes are frequent, especially in the early stages of development of ATMPs.

Every change in manufacture should be done in accordance with GMP. The criticality of the changes and the estimation of their impact on the characteristics of the product should determine the amount of comparability data needed. Where applicable, the Variation Regulation (for authorised ATMPs) or the clinical trial framework (for investigational ATMPs) should be followed.

A suitable comparability program is required to support the introduction of changes during the development stages of an ATMP. It is of importance that the changes implemented in all stages of development are fully evaluated, justified and tracked. The acceptable level of flexibility is progressively reduced from the non-clinical stage to the pivotal clinical use. The introduction of substantial changes to the manufacturing process and the final product during pivotal clinical studies are not recommended due the complexity of the comparability exercise and the possible impact of its results on the acceptability of the clinical data. In cases where late stage changes in the manufacturing process are unavoidable, it is recommended to seek for EMA scientific advice. Comparability is also an important tool to support changes after marketing authorisation where the process and the product are expected to be well defined and appropriately controlled by quality specifications and characterisation tools.

Comparability is the conclusion of the comparability exercise demonstrating that no adverse impact on the quality, efficacy and/or safety profile of a product has occurred when a manufacturing process change/transfer is introduced for the drug substance/product.

Key points to be considered when developing comparability exercise:

- inherent variability of starting materials for cell/tissue-based advanced therapy medicinal products;

- critical changes in the manufacturing of starting materials having an impact on the manufacturing process or the finished product;

- vector based gene therapy medicinal products considered as products more closely related to biotechnology in terms of manufacturing process and process controls;

- evaluation of the potential impact of the proposed change for its risks to the quality of the final product and the impact on the efficacy and safety profile of the product; a risk-based approach as a driver of the overall extent of the comparability exercise for ATMPs;

- evaluation of equivalency of manufactured products and also comparison of processes themselves (particularly important when a new manufacturing site is introduced), if relevant;

- suitable analytical tools;

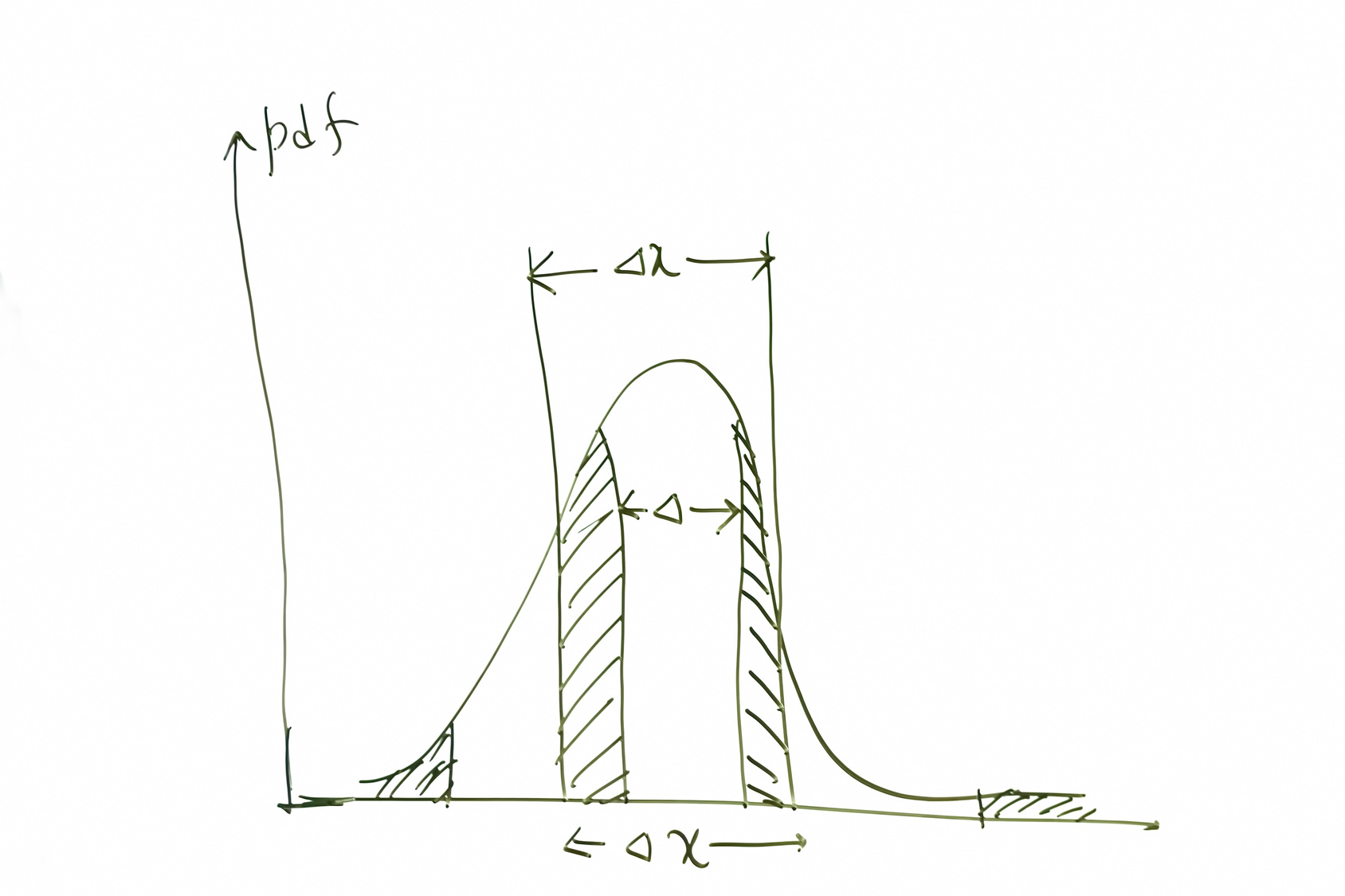

- feasible approach for demonstrating comparability – preferred side-by-side testing of products in the same analytical run vs. comparison of post-change data to historical data obtained from pre-change process;

- extend of stability studies (dedicated stability studies under accelerated or stress conditions, real-time stability studies for cells with a very short shelf life, in-use stability study, if relevant);

- suitable number of batches (the higher the variability between batches is, the higher the number of batches is required);

- selection of the statistical methodology.

Source: EMA